Eductors System

Cebeco is a renowned provider of high-quality eductors in Australia. Eductors are devices that use a fluid or gas to create a vacuum or suction effect, which can be used for a variety of applications. Cebeco offers a range of eductor products, including eductor nozzles, eductor systems, compressed air eductors, and more. Here is an overview of the different types of educators that we sell online in Australia.

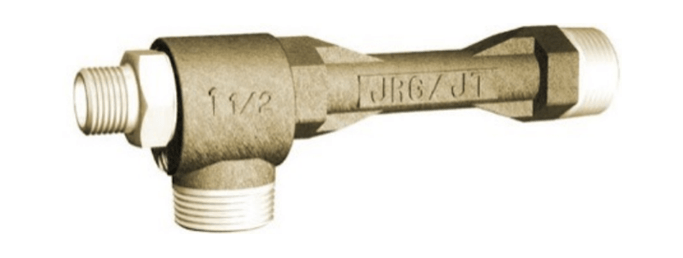

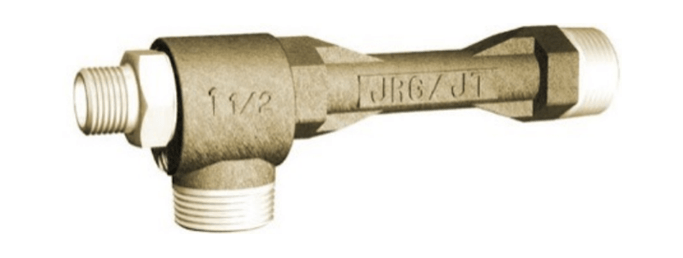

Jacoby Tarbox Eductors

Jacoby Tarbox eductors are widely used in various industries due to their effectiveness and versatility. These eductors use high-velocity fluid jets to create a vacuum or suction effect, which can be used for numerous applications such as mixing, agitation, and pumping.

In the chemical industry, Jacoby Tarbox eductors are used for chemical mixing, injection of chemicals, and in reactors. In the petrochemical industry, they are used for pumping and mixing hydrocarbons; in the food processing industry, they are used for mixing ingredients and creating emulsions.

Cebeco offers a range of Jacoby Tarbox eductors to meet the specific needs of their customers. These eductors are available in various sizes, materials, and flow rates. To ensure that customers get the right size eductor for their specific applications, Cebeco provides Jacoby Tarbox eductor sizing services. Our team of experts assesses the customer’s application requirements and provides recommendations for the appropriate size and model of eductor.

Cebeco’s commitment to providing high-quality Jacoby Tarbox eductors and excellent customer service has made us a trusted supplier in the Australian market.

Water Jet Eductors

Water jet eductors, or water jet ejectors, are popular for many industrial applications due to their simple design and efficiency. They work by using high-pressure water to create a vacuum that can be used for various purposes, such as mixing, pumping, and creating a suction effect.

Cebeco offers a wide range of water jet eductors to cater to the specific needs of their customers. These eductors include water jet ejector vacuum systems, commonly used in wastewater treatment plants to create a vacuum to remove air or gas from the water. Water jet air ejectors are used to create a vacuum for gas removal in chemical processing plants, while water jet eductor pumps are used for pumping and mixing liquids in the chemical and petrochemical industries.

Cebeco also offers Schutte Koerting water jet eductors, which are used in power generation plants to create vacuums for steam condensers. Schutte Koerting eductors are known for their energy efficiency and high suction capacity.

At Cebeco, the water jet eductors are available in different materials and sizes to cater to the specific needs of our customers. With our commitment to quality and customer satisfaction, Cebeco has become a reliable supplier of water jet eductors in Australia.

Eductor Jet Pumps

Eductor jet pumps are widely used in various industries for a variety of applications such as pumping, mixing, and fluid handling. They are devices that work by using a fluid or gas to create a vacuum or negative pressure, which is then used to move liquids, gases, or solids. The principle behind eductor jet pumps is that they utilise the Bernoulli principle, which states that when the velocity of a fluid increases, its pressure decreases.

Cebeco offers a wide range of single-stage and multistage models to cater to different industrial needs. Single-stage eductor jet pumps are used for general purpose applications, while multi-stage eductor jet pumps are used for higher pressure and flow rate requirements.

Eductor jet pumps find applications in various industries, including chemical, petrochemical, and food processing industries. They are used for mixing chemicals, transferring liquids, and cleaning tanks and vessels. In the chemical industry, eductor jet pumps are used for injecting chemicals into a process stream, while in the petrochemical industry, they are used for transferring crude oil and other fluids. In the food processing industry, eductor jet pumps are used for mixing ingredients, homogenising fluids, and transferring liquids.

In summary, eductor jet pumps are versatile devices that find applications in various industries for pumping, mixing, and fluid handling. Cebeco offers a wide range of eductor jet pumps to cater to different industrial needs.

Explore precision and reliability in fluid control with our comprehensive range of valves, strainers, and sight windows. From cutting-edge technology to durable designs, we deliver solutions tailored to your needs, ensuring optimal performance across diverse industries. Elevate your fluid management with Cebeco.

Venturi Pumps

Venturi pumps, named after their inventor, Italian physicist Giovanni Venturi, work by using the Bernoulli principle. This principle states that as the speed of a fluid or gas increases, its pressure decreases. A venturi pump takes advantage of this principle by forcing a fluid or gas through a narrow section called the venturi, which creates a low-pressure zone in the wider section of the tube.

Venturi pumps are commonly used in industrial applications for pumping, mixing, and transferring liquids and gases. They are often used in chemical processing plants, oil refineries, and wastewater treatment facilities. Because they are powered by air, they are particularly useful in environments where electricity is not readily available or electrical equipment could be hazardous.

Cebeco offers a range of venturi pumps to meet the needs of various applications. Their air-powered models are efficient and cost-effective, while their slurpy pumps are designed for applications requiring abrasive or viscous fluids transfer.

Overall, venturi pumps are a versatile and reliable solution for a variety of industrial applications, and Cebeco’s range of venturi pumps can help meet the specific needs of any operation.

Gas Scrubbers

Gas scrubbers are vital components in many industrial applications that generate gas streams, including chemical, petrochemical, and power generation industries. The main function of gas scrubbers is to remove pollutants from these gas streams before they are released into the environment. Gas scrubbers can also be used to recover valuable chemicals from gas streams, making them an essential tool in the efficient operation of many industrial processes.

Cebeco offers a range of gas scrubbers to meet the diverse needs of industrial customers. Their product range includes flue gas scrubbers, which are used to remove harmful gases and particulate matter from the flue gas generated during the combustion of fossil fuels. Natural gas scrubbers are also available, which remove impurities such as hydrogen sulphide and carbon dioxide from natural gas streams.

Gas scrubbers work by using various physical and chemical mechanisms to remove pollutants from the gas stream. These mechanisms can include absorption, adsorption, condensation, and filtration. The choice of scrubber and the specific mechanisms used will depend on the nature of the gas stream and the pollutants that need to be removed.

Overall, gas scrubbers are critical components in many industrial processes, helping to ensure compliance with environmental regulations, reduce the impact of industrial processes on the environment, and improve the efficiency of industrial operations.

If you’re looking for high-quality eductors in Australia, look no further than Cebeco. Our range of eductors includes Jacoby Tarbox eductors, water jet eductors, eductor jet pumps, venturi pumps, and gas scrubbers. Contact us today to learn more about our products and to place your order.

Eductors to pump liquids & wet solids